New approach to medical device

product

development

in Brescia

-

Medical device companies in Brescia and the University of Brescia collaborate to offer product development services

-

Vertically integrated production technologies shorten design iteration cycles and reduce costs

-

Transparent access to production technologies preserves future supply chain options

-

Accelerate innovation through knowledge sharing within a collaborative medical device ecosystem

Why Brescia

Building on its entrepreneurial and academic heritage, Brescia is a well established center of innovation.

Recent medical inventions coming from Brescia include Isinnova’s retrofitting of snorkeling masks into ventilators for Covid patients and 3D printed leg prostheses for persons who lost a lower limb in the war in the Ukraine. Meanwhile, Antares Vision is driving digitalization of products and supply chains with new data management solutions. Prominent catheter system innovations from Brescia include the first commercial drug eluting angioplasty balloon, the first below the knee stent and the first proximal carotid artery protection catheter.

MedInBrix taps the know-how and technologies that drove and grew out of these and other innovations to create service solutions for our customers.

Collaborative ecosystem

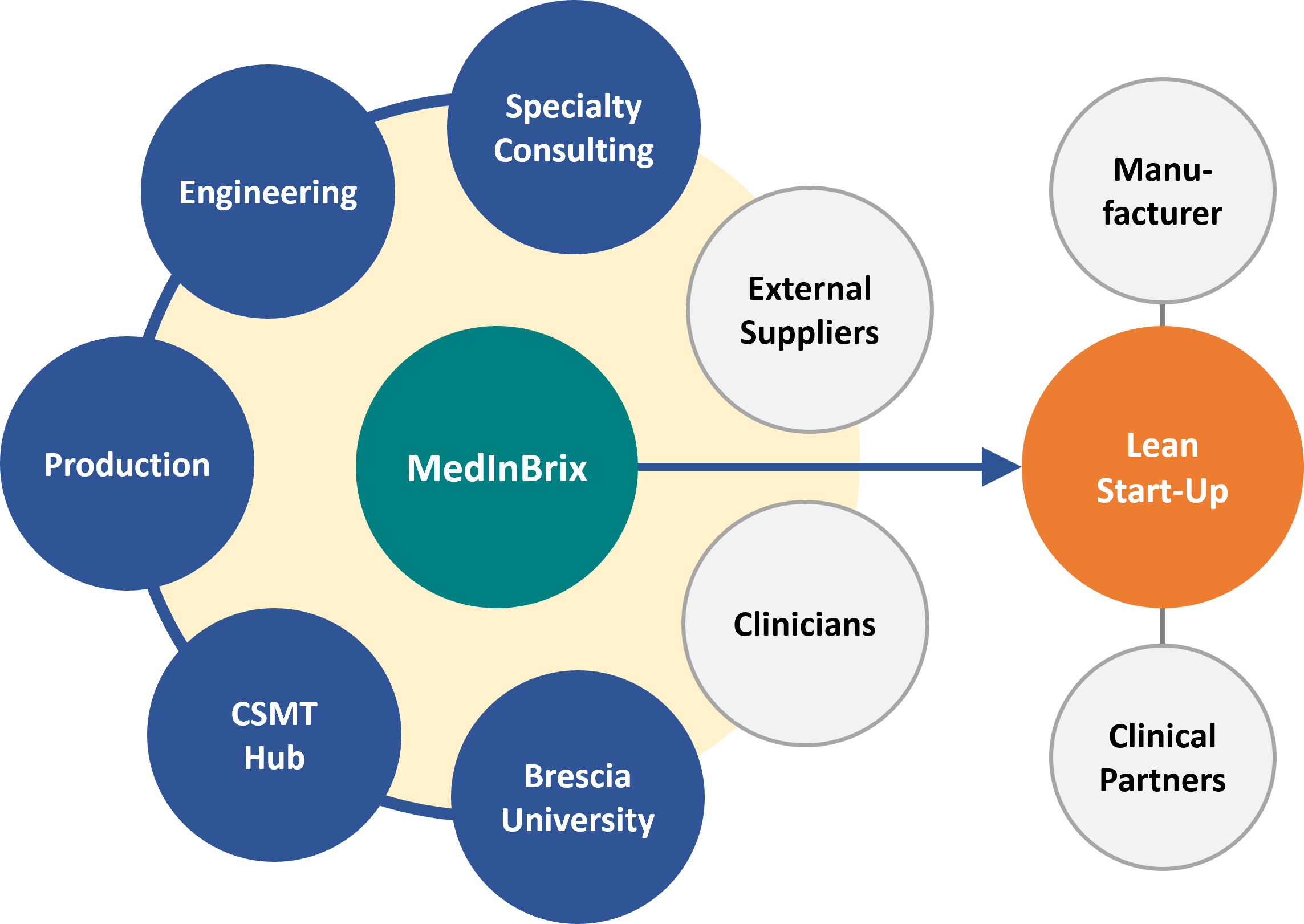

MedInBrix partner companies and academic institutions co-create service solutions and openly share know-how to support customers with product development.

Contributions from individual partners are organized into integrated services provided through MedInBrix. External suppliers complement in-house capabilities.

MedInBrix was founded in June 2023 and today partner companies collaborate to provide contract services.

The MedInBrix network will grow through the engagement of additional partners.

Addressing a market gap

Market trend

Consolidation in the medical device services industry is limiting supply chain options for start-ups

Start-up needs

The collaborative ecosystem in Brescia creates service solutions tailored to the needs of start-ups

Value

Accelerated product development and supply chain flexibility for innovators

Commitment

Customers and MedInBrix share a common mission and incentives

Understanding needs of start-ups

“Access to vertically integrated production technologies shortens design iteration cycles and creates better first generation products.”

“Providing customers and their future contract manufacturers full access to production processes makes 1:1 production transfers a reality and preserves supply chain options during commercialization.”

MedInBrix and our partners offer a broad range of services and technologies for the development and manufacture of catheter-based medical devices

Our services

Product development

Rapid prototyping

Design development

Manufacturing process development

Verification and simulated use testing

Regulatory submission and IP documentation

Project management

Tooling

Silicone molding, coating and bonding

Metal and polymer 3D printing

Electropolishing

Pin and die manufacture (extrusion)

Balloon tooling

Component manufacture

Extrusion (multilayer, -lumen)

Balloon forming (dipping and blowing)

Braid and coil manufacture

Metal and polymer laser cutting and welding

Nitinol heat treatment

Electropolishing

Assembly

Clean room assembly (ISO 13485)

Injection/over- molding

Printing (ink and laser)

Handle manufacture

Soldering and point welding

UV and epoxy gluing

Tip forming

Lamination

Shape setting

Swaging (marker band fixation)

Balloon folding

Pouch sealing

Packaging